History

Even the Alps started off small. Like the mountain range at the heart of Europe, Hoval has grown into a firmly established entity: diverse, prominent, extraordinary. A look back reveals a fascinating history. We see a small metalworking shop in Vaduz, ground-breaking inventions and far-reaching decisions.

It all began with a multi-functional stove that could be used for both cooking and heating. For the first time, Hoval made its vision a reality: greater energy efficiency in a single combined system. Inspired by this simple yet ingenious idea, Hoval built increasingly sophisticated heaters for diverse energy sources. Systems for ventilation and cooling soon extended the product range. Today, this broad expertise has given rise to intelligent system solutions for a pleasant indoor climate.

The early years build the foundation

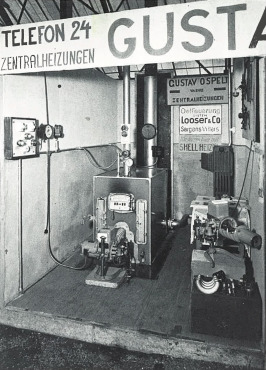

1897:

Gustav Ospelt senior opens a metalworking shop in Vaduz in the Principality of Liechtenstein.

1932:

Gustav Ospelt obtains the authorisation to build heating systems.

1942:

The cornerstone is laid: a simple stove gives rise to a central heating system. Gustav Ospelt patents his idea and the EMPA (Swiss Federal Laboratories for Material Science and technology) confirms its high efficiency in a test report for the first time.

1945:

The "Hoval" brand is registered. The name stands for Heating equipment construction Ospelt Vaduz Liechtenstein.

1946:

First internationalisation with the establishment of companies in Austria and Switzerland.

1953:

The first boiler with an integrated hot water tank, the Hovaltherm, nicknamed "the rocket", revolutionises the European boiler market.

1955:

A licence agreement with the Friedrich Krupp steel company for steel boilers generates rapid growth and opens up the German market for Hoval.

1957:

Construction of the "Neugut" site in the Vaduz industrial zone. Since then, this has been the headquarters of the Hoval group of companies.

1957-1967:

During this decade, companies are founded in Great Britain and Italy, and additional favourable licence agreements are signed.

New technologies revolutionise the market

1960:

The first compact combination boiler with separate combustion chambers for liquid, gaseous and solid fuels is ready for the market – in eight different versions.

1967:

The first high-performance water heater, Modul-plus, still guarantees the highest levels of hot water comfort today, perfoming superbly under fluctuating peak requirements while meeting the most stringent water hygiene specifications.

Hoval celebrates a milestone: the 100,000th boiler leaves the Vaduz works. In all of Europe, 350,000 Hoval boilers have already been built by this time.

1968:

Hoval receives its first heating surfaces patent, called the “Fischgratrohr”, or “fish-bone tube”, which achieves enormous gains in heat transfer and therefore in efficiency. Further heating surface patents follow.

1970:

Expansion of the product spectrum to include industrial ventilation units and aluminium plate heat exchangers for energy recovery in climate control and ventilation systems and in processing technology.

1976:

Introduction of a decentralised device for ventilating industrial halls with heat recovery. Use of this device reduces heating energy needs by up to 60 percent.

1979:

Registration of a trend-setting patent: the self-cleaning thermolytic heating surface. An entire series of small and medium-sized boilers is named for the Hoval achievement: their names end in “Lyt”.

1982:

Hoval starts a development project with Ruhrgas Deutschland for gas premix burners. These burners guarantee particularly low levels of pollutants during combustion. The new development enters into series production in 1986 under the name of Ultraclean.

1984:

Hoval develops a unique vortex air distributor, the Air-Injector, for even greater efficiency in the ventilation and heating of industrial halls.

Focus on efficiency and environmental consciousness

1987:

With the wood gasification boiler, Hoval introduces gasification technology for biomass. The three-stage combustion method soon becomes the market standard.

1993:

Research on the most efficient condensing technology culminates in the patented Hoval aluFer, a heat exchanger with an integrated aluminium microstructure. Energy efficiency, cost savings and a long service life are only some of the advantages of a whole generation of gas condensing units, which first went into series production in 1994.

1994:

The patented technology of the first Hoval recirculation cooling unit makes cost-effective heating and cooling of high spaces possible with just one device.

1999:

Hoval launches the MultiJet oil condensing boiler, with a revolutionary heating surface. Its technology with jet inserts achieves optimal heat transfer levels, resulting in excellent efficiency, very quiet running and an exceptionally compact design.

2001:

The use of alternative energies enters a new dimension with the development of the horizontal tube burner for pellet boilers. Efficient, compact, reliable and comfortable – these words describe the conversion of wood to heatby the BioLyt series.

2001-2004:

Hoval expands its worldwide sales network to include its own branch offices in Poland, the Czech Republic and Slovakia.

2004:

Hoval develops a special sorption coating for thermal wheels, which transfers not only heat but also humidity. This technology creates a constant, pleasant indoor climate and superb living comfort by means of ventilation systems featuring cooling or humidity control, such as the HomeVent controlled home ventilation system.

2005:

After over 20 years of doing business in China, Hoval establishes its first sales company in Asia.

2006:

UltraOil, the first oil condensation unit based on the aluFer heat exchanger, goes into series production. Today, this is a highly successful product group that generates power outputs of 16 – 600 kilowatts.

Hoval is entering new areas

2006-2008:

The newest Hoval sales companies open their doors in Romania, Spain, France and Croatia.

2007:

Environmentally friendly cooling with refrigerant-free recirculation, not only reducing water consumption but achieving maximum adiabatic efficiency levels.

2008:

Hoval invests in the production of heat pumps with Wärmepumpen GmbH in Matrei (WPM), East Tyrol.

2010:

Hoval introduces a new business sector of heat transfer stations and combined heat and power plants.

2011:

New design: The red colour and dynamic lines express self-confidence.

Bulgaria and Singapore join the international Hoval locations.

2013:

Hoval builds up a production line in Vaduz for manufacturing the UltraSol thermal solar collector. Its design is unique: a barely visible aluminium profile assembles the collector tiles and the installation appears homogeneous on the roof.

2014:

A new branch in Denmark represents Hoval in Scandinavia.

The acquisition of the Swedish company Enventus AB strengthens Hoval's energy recovery business.

2015:

Hoval celebrates its 70th anniversary.

Digitalisation takes hold: Using the newly introduced TopTronic E control platform, a wide range of Hoval heat generators can communicate online and adjust their operation to the weather forecast.

2016:

Hoval strengthens its district heating/heating networks division and acquires the German company YADOS GmbH.

Hoval is ready for the digital future

2018:

Hoval solutions are optimised by digital networking.

2020:

Hoval uses state-of-the-art technology and natural refrigerants to operate the new generations of heat pumps.

The patented TurboFer heat exchanger goes into series production.

2021:

Hoval introduces the IoT platform HovalConnect and the new generation UltraGas 2 with patented TurboFer heat exchanger.